Author: Ralph Bockisch

created on: 08.01.2026, last change: 04.02.2026

Table of content

Planned maintenance vs. spontaneous deployment - a daily dilemma

Fictitious example: Two calls, one technician - the wrong decision

How modern field service management solutions combine both worlds

Solution approach: Technician dispatching with EcholoN FMS

Frequently asked questions about technician dispatching and deployment planning

Monday morning, 9 a.m., in the service control centre: The first technician is on a maintenance call at a customer's site when suddenly the phone rings. Fault report! An important machine has broken down and another customer is demanding immediate assistance. However, your only available technician is still in the middle of scheduled maintenance. What now? Should he interrupt the maintenance work to deal with the machine breakdown, causing a delay for the first customer? Or should he continue with the maintenance and leave the machine breakdown to wait, thereby extending the downtime for the second customer? Both options are critical and require a quick, smart decision.

Such scenarios are not uncommon: For many service managers, dispatchers and resource planners in technical customer service, they are part of everyday life. Dispatching technicians is like walking a tightrope every day between well-planned maintenance scheduling and unforeseen breakdown calls. Planning meets reality – and it is not uncommon for even the best plan to be thrown off course. How well is your planning prepared for the unpredictable?

Planned maintenance vs. spontaneous deployment - a daily dilemma

Maintenance work follows a long-term plan to keep systems running reliably. But when an acute malfunction occurs, it usually takes top priority - downtime costs money and customer satisfaction. So a planned task often has to be postponed in order to deal with an emergency. The result: the carefully crafted maintenance plan is thrown into disarray. What specific problems arise when an unplanned intervention disrupts the routine? Here are a few examples from everyday service work:

- Postponed appointments: Planned maintenance or installations have to be rescheduled at short notice. This upsets customers and can jeopardise contractually guaranteed deadlines.

- Resource conflicts: A technician cannot be in two places at once. If he is withdrawn, he is missing elsewhere. Without sufficient reserves, staff shortages quickly arise in the team.

- Longer response times: Valuable time is lost until a replacement technician is found or a new appointment is coordinated. Unplanned waiting times can lead to escalations - especially if service level agreements (SLAs) could be violated.

- Cost and time pressure: Ad hoc assignments disrupt route planning. Technicians take detours or travel twice the distance, which results in additional travel costs and working hours. Overall efficiency suffers.

- Stress and communication problems: Dispatchers are under high pressure to reschedule spontaneously. In the hectic rush, the risk of coordination errors increases - for example, a customer not being informed of delays in time.

Fictitious example: Two calls, one technician – the wrong decision

Service dispatcher Martin M. faces precisely this dilemma. On a Tuesday morning, he receives two urgent requests at almost the same time: Customer A has scheduled preventive maintenance for an important machine, while Customer B has suddenly experienced a breakdown in a production facility. Both require immediate attention. However, Martin's only available technician can only go to one location. Under time pressure, Martin decides to complete the ongoing maintenance at customer A as planned before sending the technician to customer B.

At first, this seems reasonable – but while the technician is still busy at customer A, production at customer B comes to a standstill. When the technician arrives there hours later, the customer is angry and has already escalated the issue to the service manager. Martin's decision turned out to have serious consequences: contractual penalties for exceeding the response time and a damaged customer relationship. This example shows that without transparent real-time information and clear priorities, it is extremely difficult to always make the best decision. This is where modern digital tools can help.

How modern field service management solutions combine both worlds

Fortunately, there are now ways to resolve this conflict. Modern field service management systems and smart planning approaches help dispatchers to reconcile predictability and flexibility. Some tried-and-tested methods are:

- Skill matching: Using a skills matrix, planners can ensure that the right technician with the necessary skills is always assigned to the job. This avoids wasted journeys or delays because an employee without the necessary qualifications was sent.

- Intelligent route optimisation: Software-supported route optimisation minimises travel times. Orders can be grouped together geographically in a sensible way, and the best sequence of appointments is calculated automatically. Technicians are more efficient on the road and can more easily squeeze in an additional ad hoc appointment during the day without all other customers having to wait too long.

- Real-time transparency & communication: Modern solutions offer real-time insights: dispatchers can see live which job is currently in progress and where each technician is located. Changes or new orders can be immediately transmitted to the technician's mobile app. At the same time, customers can be automatically informed of delays or a new estimated arrival time. This transparency prevents information gaps and makes spontaneous rescheduling much easier.

- Prioritisation and buffer times: Important criteria such as urgency, SLA requirements and customer priority are stored in the system. A good planning tool helps to immediately identify and prioritise critical cases. Ideally, a buffer time should also be planned in – this allows a technician to intervene if the unexpected happens without completely disrupting the entire daily schedule.

Such approaches allow you to significantly improve response times without neglecting regular maintenance. In other words, planning and spontaneous flexibility can be combined when the right tools are used.

Would you like to know how efficient your current scheduling is?

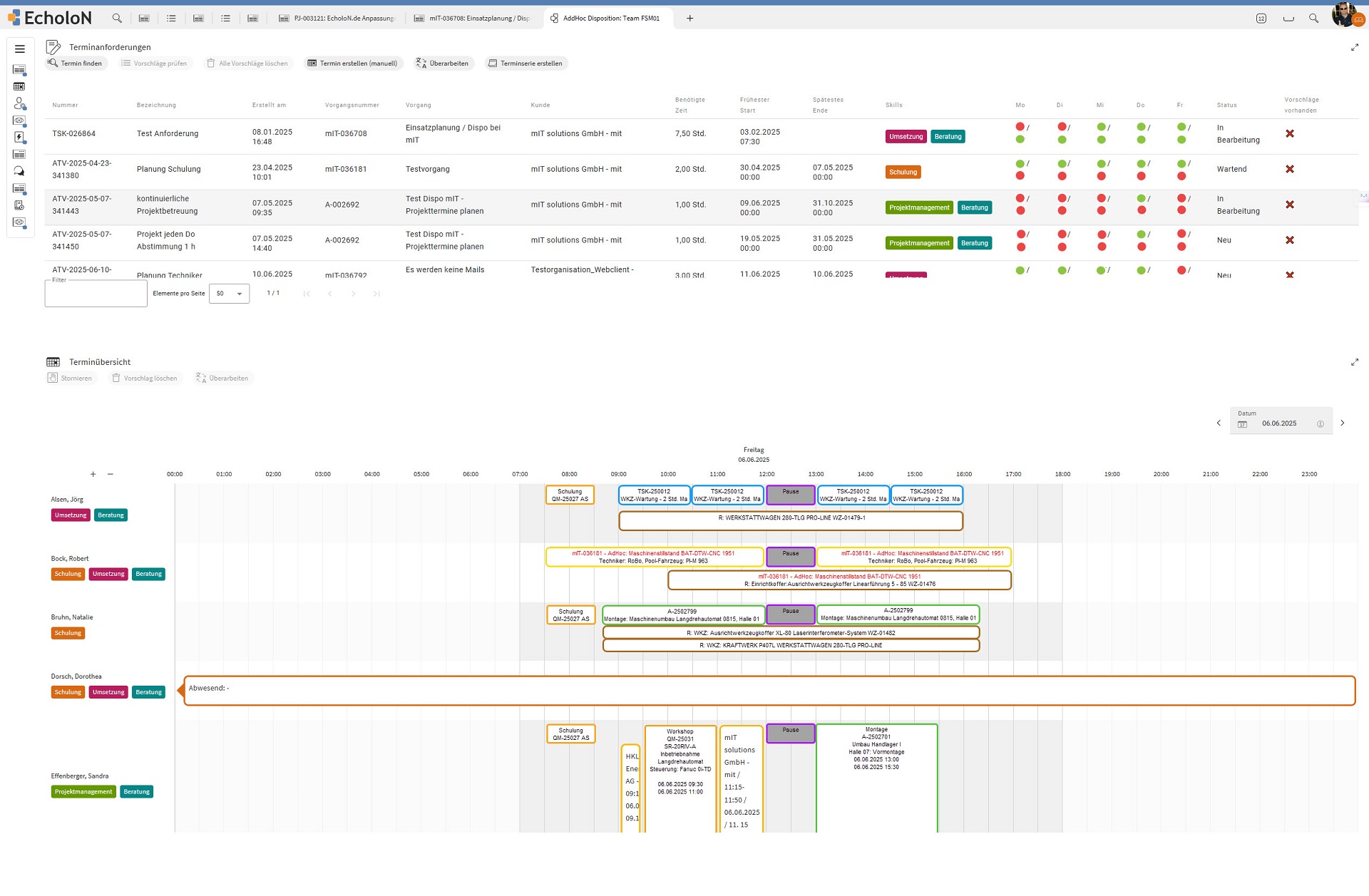

Solution approach: Technician scheduling with EcholoN FMS

A software solution such as EcholoN Field Service Management (FMS) Made in Germany. EcholoN covers the entire process, from ticket entry and resource planning to mobile service reports.

For the scheduling of technicians in practice, EcholoN offers in particular:

- Flexible scheduling models: any parameters, such as skill, certification, customer SLA, etc.

- Flexible route planning

- Automatic escalation logic

- Direct integration with other upstream and downstream systems

Conclusion: Balancing predictability and responsiveness – increasing productivity

Planned maintenance versus spontaneous repairs does not have to be an irreconcilable contradiction. With the right strategies and tools, today's balancing act in technician scheduling becomes a manageable task in which neither maintenance routines nor rapid assistance in emergencies are neglected. When your resource planning has both preventive maintenance and acute service calls under control, everyone benefits: your technicians are working at optimal capacity, your customers are more satisfied, and your service team stays calm.

Are you familiar with the challenges described?

Frequently asked questions about technician scheduling and resource planning

What does technician scheduling mean?

The term technician scheduling refers to the organisational planning and allocation of service technicians to assignments. It therefore involves the resource planning of technicians in the field – all measures taken to deploy the right technicians to the right place at the right time. This includes scheduling, route planning, coordinating qualifications and assigning suitable employees to jobs. Efficient technician dispatching ensures that service jobs are completed smoothly and promptly and that no job is missed.

How can response times in service be improved?

To improve response times, service processes should be optimised and accelerated. It is important, for example, to clearly prioritise incoming fault reports so that urgent cases are immediately identified and processed. The introduction of a field service management system also helps: dispatchers can immediately see which technicians are available and where they are located, and can coordinate the appropriate assignment without delay. Team training, defined emergency plans and good spare parts availability (e.g. through connection to the warehouse) also help to shorten response times for service calls.

What is route optimisation in field service?

Route optimisation in field service refers to planning service technician routes in the most efficient way possible. Appointments and locations are coordinated in such a way that technicians have as little idle time and travel time as possible. Modern route planning uses software and intelligent algorithms to calculate the best sequence of customer visits based on geodata, traffic information and order priorities. The result is shorter travel distances, lower costs and often faster response times for customers, as more orders can be completed per day.

How can maintenance planning and ad hoc service calls be reconciled?

The key to successfully reconciling maintenance planning and ad hoc service calls lies in flexibility and overview. Today, companies rely on digital planning boards and field service management software that integrates both: recurring maintenance appointments are entered there, but can be dynamically rescheduled if necessary. At the same time, ad hoc faults can be marked as high-priority tickets and seamlessly inserted into the existing schedule. It is important to always allow for a certain buffer in the deployment planning and to set clear rules for priorities. This ensures that scheduled maintenance is not neglected, while urgent cases are still dealt with immediately.

How can service calls be coordinated effectively?

To coordinate service calls effectively, up-to-date information and a good planning system are essential. A dispatcher should always know which technicians are available or nearby and which jobs have priority. Centralised software that records all service orders and displays their status in real time is helpful. With such an overview, new assignments can be optimally distributed without jeopardising other appointments. Regular team meetings (e.g. daily briefings) also help to ensure that all upcoming service assignments are coordinated and run smoothly.

How can maintenance efficiency be increased?

Maintenance efficiency can be increased by proactively preventing breakdowns and optimising processes. On the one hand, there should be a well-thought-out maintenance plan that includes regular inspections and preventive maintenance – this reduces unplanned downtime. On the other hand, the use of maintenance software or a CMMS system (Computerised Maintenance Management System) helps: it reminds you of due maintenance, manages spare parts and allows the evaluation of fault data to identify weak points. In addition, training maintenance personnel and good internal communication help to carry out maintenance work faster and more efficiently.

What is EcholoN FMS?

EcholoN FMS stands for EcholoN Field Service Management. It is a software solution from mIT solutions GmbH that supports companies in managing their technical services. EcholoN FMS offers functions for all aspects of field service management: e.g. a central ticket system, graphical resource planning and route planning, mobile apps for technicians and much more – all integrated into one platform.

Thanks to its high adaptability (modular configuration without programming) and the option of connecting to existing systems such as ERP or CRM, EcholoN can be flexibly adapted to the needs of different organisations. Many companies, such as McDonald’s and Transdev, are already successfully using EcholoN to streamline their service processes and ensure both predictability and fast response times.

Also interesting:

- EcholoN FSM - Field Service Management Software

- Customer service & customer support and after-sales service

- CMMS - Maintenance software for reliable processes

- Blog article: Route optimisation in field service

- Blog article: Difference between maintenance, inspection, servicing and repair and overhaul